EN

EN  EN

EN  2023-04-17 09:54:53 / Visits: 415

2023-04-17 09:54:53 / Visits: 415

Hydraulic system exhaust

The exhaust of a hydraulic system usually refers to the first action after a new installation or maintenance is completed, excluding the presence of air in the pipeline. The hydraulic system requires good continuity of hydraulic oil during power and signal transmission. If the hydraulic system is mixed with air, it will lose its inherent stiffness and continuity, and cannot guarantee the stability and reliability of the hydraulic system operation.

Danger of entering the air

Once the hydraulic system is mixed with air, it may cause the following four hazards:

Firstly, bubble pressure may generate high temperatures, which will cause the hydraulic oil to heat up.

2. The air contains a certain amount of oxygen, which will accelerate the oxidation of hydraulic oil and system components.

Thirdly, bubbles may cause oil film formation between moving parts, leading to poor lubrication and exacerbating wear of hydraulic components.

4. The pressure impact caused by bubble explosion after high pressure will cause corrosion of hydraulic components.

The above four hazards may cause hydraulic system failures and shorten the service life of hydraulic components.

Taking excavators as an example

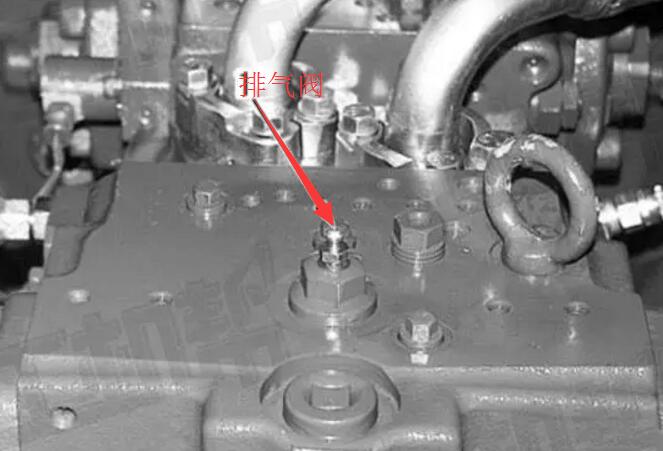

1、 Hydraulic exhaust pump

1. Loosen the exhaust plug and confirm that oil has escaped from the exhaust plug.

If oil leakage is confirmed, please tighten the exhaust plug.

3. Exhaust plug: 7.8-9.8 Nm (...) 0.8-1.0 kg General Motors)

As mentioned above, when starting the engine after exhaust work, run the engine at low idle for 10 minutes. If the engine coolant temperature is low and the automatic preheating function of the engine has been used, it can be cancelled using the fuel control knob when needed.

(2) . Hydraulic cylinder exhaust

1. Start the engine and maintain low idle for 5 minutes.

2. When the engine is at low idle, raise and lower the arm 4-5 times.

Be careful not to apply overflow pressure and stop the piston rod approximately 100 millimeters before the end of the stroke.

3. When the engine is at high idle, repeat the above steps.

4. Apply overflow pressure, extend the piston rod until the end of the stroke, and run the engine at low idle speed.

5. Follow the same steps as before 2-4 to exhaust the stick cylinder and bucket cylinder.

As the cylinder has been replaced with a new one, it is recommended to unload it from the new cylinder before installing the working device. Especially after installing the working device, the boom cylinder cannot extend to the end of the lower stroke due to the connecting rod.

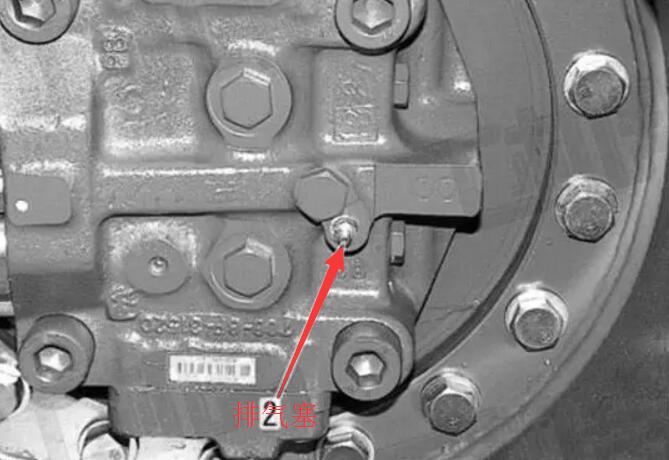

3、 Travel engine exhaust

1. Start the engine and run at low idle.

2. Loosen the exhaust plug and confirm that oil has escaped from the exhaust plug.

3. If oil leakage is confirmed, tighten the exhaust plug 2: 27.5-35.3 Nm (...) 2.8-3.6 kg GM“

4、 Rotating engine exhaust

1. Start the engine and run at low idle.

2. Slowly rotate the upper rotating platform to exhaust.